Inventory Optimization

Companies selling products to customers want to service as much of the demand for their product as possible. But, the future is uncertain. It is impossible to know exactly what the product demand will be. Even remembering what a product sold for this month last year is hard when a planner's inventory holds hundreds or thousands of products. Warehouses have limitations, and companies don't want to tie up their liquidity in products to put on shelves unnecessarily. The hours planners have in a day is limited, and they have to make purchase decisions for a huge number of inventory products.

Inventory Optimization is about enabling stock-holding companies to have the right products in stock at the right times, while spending less time and resources on the process. Developing and offering advanced inventory optimization functionality involves expertise in AI, specifically forecasting with machine learning techniques and applied mathematical optimization.

Overview

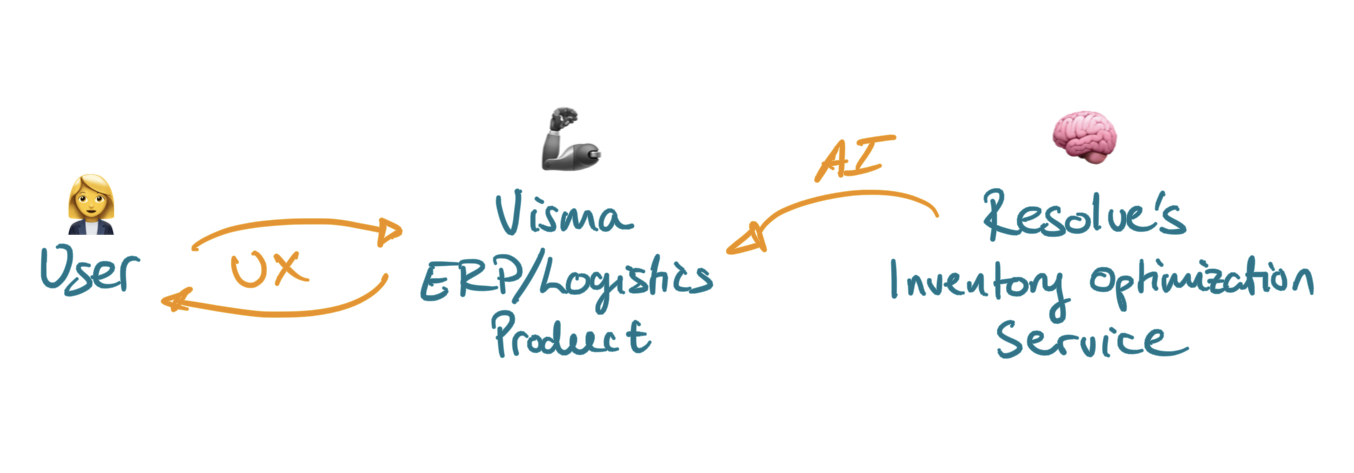

Visma's ERP products offering logistics planning have a massive potential to utilize Inventory Optimization to improve their service offering. By applying AI in the realm of inventory management, existing user workflows can be improved. Taking it a step further, it can enable entirely new ways of working with inventory. The question is how to get there.

Inventory Optimization makes inventory management AI functionality accessible to all of Visma's ERP products. Our goal is to enable these products to go to market with this cutting edge technology, and to do so fast.

To achieve this, we have built the IO service as an API. The API wraps all AI functionality needed for creating a next-generation inventory management system. This includes forecasting future product demand and generating purchase order suggestions for all of the products in a company's portfolio. It also includes functionality for classifying inventory products. This way, Visma's ERP products can integrate with the API and get smart inventory functionality powered by AI directly into their system.

Note that the terms "planner", "user", and "end-user" will be used interchangeably in this documentation. We use the term "partner" for the Visma ERP integrating with the Inventory Optimization API.

Features

The features of Inventory Optimization include:

- Demand forecasts

- Break-down of each forecast value into season, trend, and noise

- Upper and lower bounds on each forecasted value

- Purchase order suggestion

- Reorder point suggestion

- Safety stock suggestion

- ABC classification

- Demand type classification

- Trend and seasonality identification

All this is tailored to each specific product of our partners' end-customers. Each product gets its own ML model tailored to its historical demand data. These features enable our partners to build an AI-assisted purchase process, where the human is kept in the loop, empowered with deep insight and tailored suggestions. See the pages under the Build section for more details about the UX that can be built, and the Core Concepts section for a deeper explanation of the core concepts behind these features.

Documentation Outline

This documentation covers the following:

- Quickstart - get up and running with the API in less than 1 hour.

- Core Concepts - learn the core concepts of Inventory Optimization.

- Integration - integrate your ERP/WMS with the Inventory Optimization API.

- Build - the UX you can build enabled by Inventory Optimization.

- Authentication - set up the Visma Connect authentication process.

- API reference - the technical details about all endpoints in one place.

Data Policy

Read about our data policy here.

Contact

Please reach out to Moa, Thea, or Anders if you have any questions or concerns.