Purchase Order Suggestions

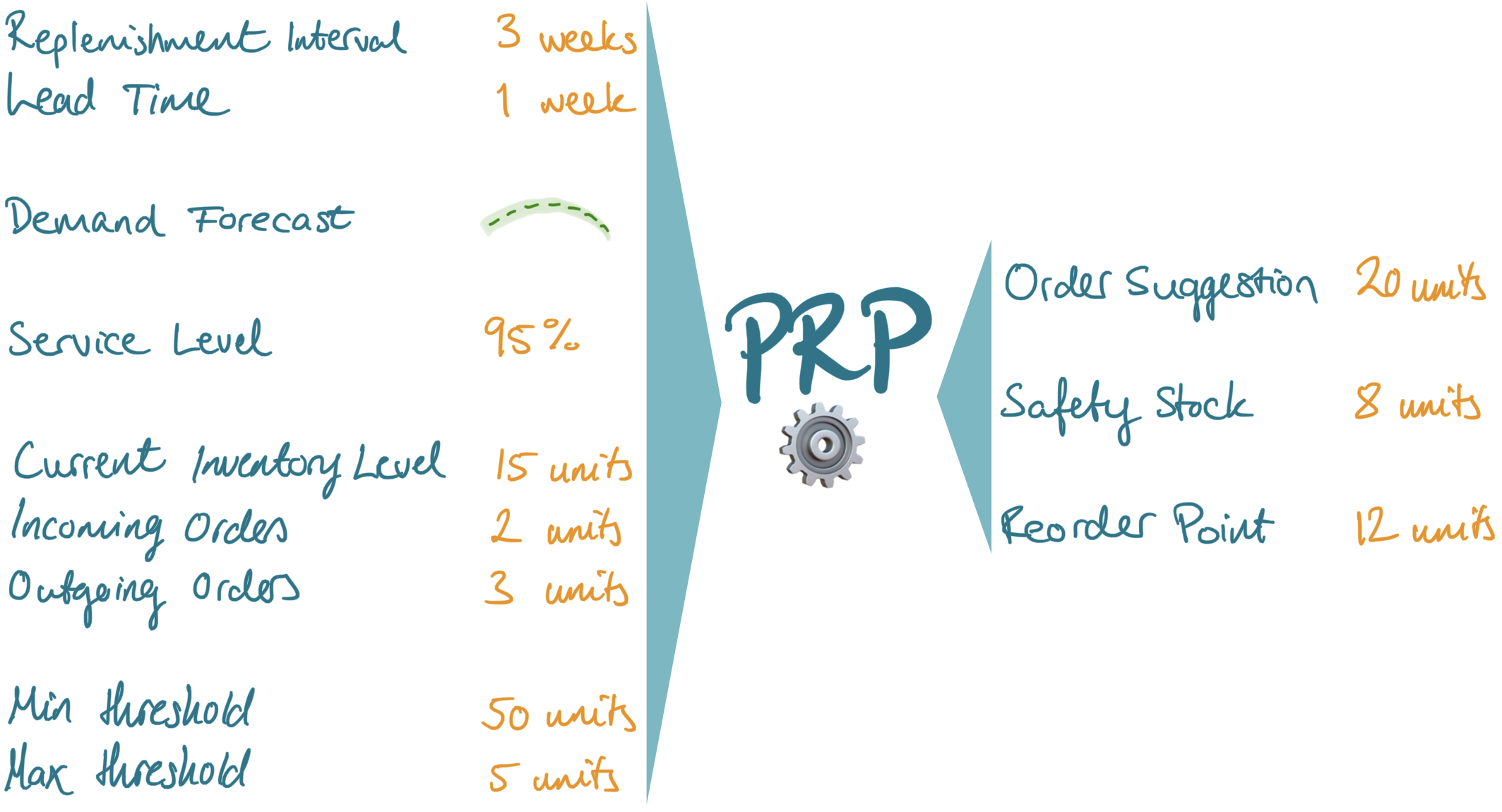

The central output from Inventory Optimization is the purchase order suggestion. This is the order quantity that the planner is adviced to purchase for a stock item in a forthcoming period. The order suggestion is based on the demand forecast and a number of input parameters that the planner sets. In addition to purchase order suggestions, Inventory Optimization also suggests values for the reorder point and safety stock of a product. Calculating the purchase order, reorder point, and safety stock suggestions for a product is referred to as the Product Replenishment Problem (PRP). The rest of this page contains a description of how Inventory Optimization solves this problem.

The Product Replenishment Problem

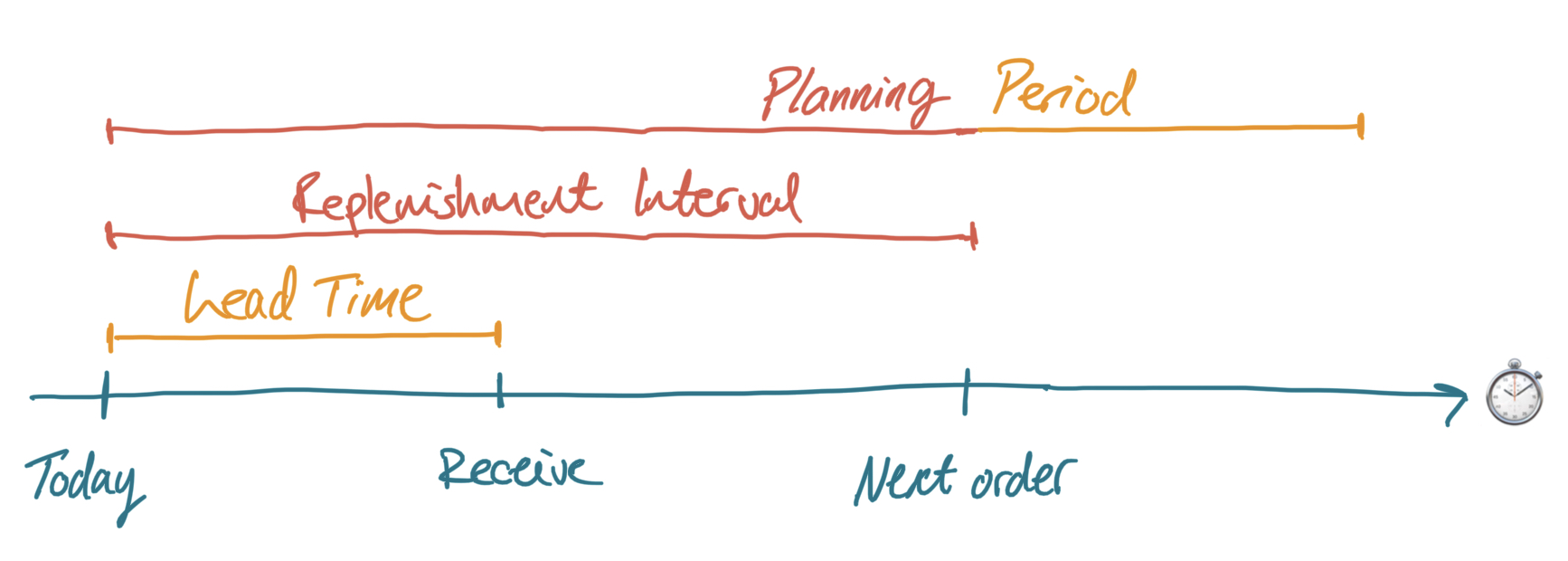

In the PRP, the planner orders a product from a supplier to service the demand for the product in a coming period. The planner sets a time to next order defining the time period that will pass before the product is ordered again. For example, if the time to next order is set to two weeks, the next time the product will be ordered will be after two weeks have passed. The product also has a lead time, which is the time it takes for the product to be shipped from the supplier to the warehouse after the order has been placed.

The planning period is the time interval for which demand needs to covered. For example, if the planning period is the next fifty days, the planner needs to order enough product items to service the demand for the product over the course of the next fifty days. In the PRP, the planning period is set to the sum of the time to next order and the lead time. The reason is that after an order has been placed for a product, the next possible delivery time of the product is when the time to next order and the lead time has passed.

The term "replenishment interval" will be updated to "time to next order" in the below figure.

The demand for the product in the planning period is uncertain. In the PRP, the demand is forecasted using machine learning techniques, as explained in Forecasts. The forecast is used as the estimate for how many product units will be sold in the planning period.

The planner also defines a service level. The service level is the percentage of product demand that the planner wants to be able to service in the long run. For example, if the service level is 98%, the planner is fine with not having enough units in stock in 2% of the cases where a customer demands the product, i.e. missing 2 out of 100 sales. The reason for defining this service level is that there is a trade-off between income on servicing demand and cost of keeping inventory. The service level is a way to parameterize this trade-off, enabling the planner to make their prioritization explicit.

The current inventory state is also taken into account when solving the PRP. The current inventory state consists of three elements: (1) the current level, (2) the outgoing orders, and (3) the incoming orders. The current level is the number of product units in inventory in the beginning of the planning period. The outgoing orders are sales orders for the product that are to be shipped to customers in the planning period. The incoming orders are orders that are coming in to the inventory from suppliers in the planning period. When solving the PRP, the order suggestions are adjusted for the current inventory and the incoming inventory orders. The forecasted demand is also adjusted for the already known outgoing sales orders, such that the forecast will always at least be equal the already known demand.

The planner can choose to operate with minimum and maximum thresholds for the product to keep in the inventory. The minimum threshold is the lowest number of product units the planner will keep in stock, and vice versa for the maximum threshold. A purchase order suggestion will take these thresholds into account if they are provided, and will not suggest a replenishment that falls below or exceeds these limits. Therefore, the limits should only be provided if there are physical limitations in the planner's inventory. If the limits are not provided, the suggestion will not be constrained.

A product has one or more suppliers. Each supplier sells the product at a unit price, i.e. the price of one product unit. They also operate with a lead time for the product, as defined previously. Furthermore, the suppliers may sell the product in batches, each batch containing a certain number of product units. Note that the unit price, lead time, batch size, and minimum order quantity can, and often will, differ from supplier to supplier.

The objective of the PRP is to order the correct quantity of the stock item in question. "Correct" means the quantity that achieves the service level set by the planner. To achieve this objective, the most important output from solving the problem is an order suggestion for the product. This order suggestion is essentially the number of product units that the planner should order to cover the estimated demand in the planning period. Taking the order suggestion into account, the planner makes a decision on how many units to order.

Also included in the output, is suggestions for safety stock and reorder point, which will be explained in the section below.

Suggestions Explained

Safety stock

The safety stock is an extra amount of inventory that we aim to maintain at all times, to cover the difference between our prediction and the actual demand. The size of the safety stock is dependent on the variance of the historical data in the last two years and the service level.

If the data indicates stable demand, a smaller safety stock is needed, whereas with volatile demand, a larger safety stock is necessary to accommodate unpredictable fluctuations. Moreover, if we want to achieve a high service level, we will need a larger safety stock to make sure we can cover the demand at all times. On the other hand, if we are fine with a lower service level, we are okay with not always being able to cover the demand, and the safety stock can therefore be smaller.

Reorder point

The reorder point is the inventory level at which a new order should be placed. The reorder point is dependent on the estimated sales in the lead time, the safety stock, and incoming orders in the planning period.

The longer the lead time is, the higher the reorder point will be, as we need to order in time to not get out of stock.

Order suggestion

The order suggestion is what we suggest you should order if you have to replenish today. This is dependent on the demand forecast, the safety stock, the incoming orders, the future sales orders, and the current inventory.

For instance, if a large order is expected to arrive soon, we will take that into account when suggesting what you should buy today.

Using the Forecast to Calculate Suggestions

When a purchase order suggestion is calculated in the middle of a time step, for example a month, we are careful not to mix up sales that have occurred so far in the month with the forecast for the month. Continuing the example from Forecasts where suggestions are requested on October 14th and the data is aggregated on months, the purchase order suggestions are calculated based on the forecast for October minus the sales that have occurred before, but not including, October 14th. To link this to the planning period, let's say that the time to next order is set to one week, and the lead time for the product is also one week. That gives us a planning period of two weeks, ranging from October 14th to October 28th. The purchase order suggestions would then be calculated based on the forecast for this period only.